Pasteurization, a pivotal technology in food safety, has effectively reduced the risk of foodborne illness and safeguarded the health of millions of people. This article explores the principles of pasteurization systems, the different types, technological advances and applications to help you fully understand this key technology.

Pasteurization is a process that prevents spoilage by heating food (usually liquids such as milk, juice and beer) to a specific temperature and keeping it there for a certain period of time to kill harmful microorganisms. After heating, the food is cooled quickly to maintain freshness. Although pasteurization does not completely kill all microorganisms, it significantly reduces the risk of foodborne illness and makes food safer to eat.

Pasteurization methods vary depending on the type of food and the desired results. Commonly used methods include:

In recent years, significant advances have been made in pasteurization technology, resulting in significant improvements in food safety, quality and process efficiency. Automation and advanced process control systems allow processors to precisely control pasteurization temperature, time and cooling cycles, ensuring consistent product quality, reducing energy consumption and minimizing human error.

The integration of advanced Cleaning-in-Place (CIP) systems revolutionizes the approach to sanitation in heat treating facilities. These systems automate cleaning cycles to ensure consistent and repeatable results with every use. By automating essential cleaning tasks, these innovative systems dramatically reduce downtime, lower chemical and water consumption, and reduce operator exposure to potentially hazardous cleaning agents, resulting in improved operational efficiency and workplace safety.

Pasteurization is not simply a “heat shock”. To understand what heat does to bacteria, we need to understand the structure of bacteria. Bacteria are single-celled organisms with a cell structure consisting of a cell wall, a cytoplasm and a flagellum (in some bacteria). The cell wall protects the internal structure of the cell, the cytoplasm contains various substances that bacteria need to survive, and the flagellum helps the bacteria to move.

High temperatures denature bacterial enzymes, causing them to become inactive and unable to perform their functions. High temperatures also damage the cell wall of the bacteria, leading to increased pressure inside the cell and eventual cell rupture and death.

Heat treatment refers to a range of heat treatments used in food processing. The purpose of heat treatment is to kill pathogens and inactivate enzymes that cause negative changes in food during storage. Pasteurization is one of the milder heat treatments. Ultra-high temperatures and sterilization methods kill all the microorganisms in the food, whereas milder heat treatments (such as heat treatment and pasteurization) kill only some of them.

Lower temperatures are chosen for pasteurization in order to maximize the retention of nutrients and flavor while ensuring food safety. Higher temperature treatment kills more pathogens but will change the characteristics of the food. For example, the protein structure of milk will be altered, affecting its taste and performance in the preparation of other foods such as cheese.

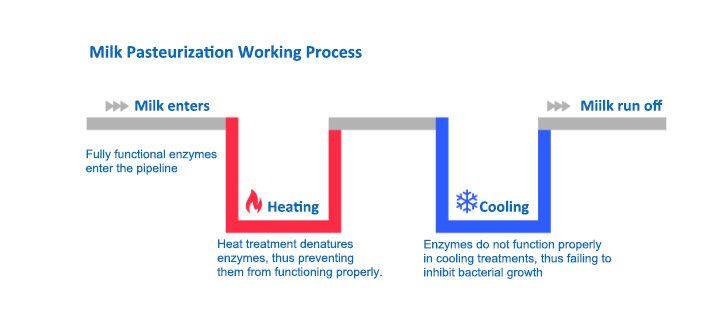

The pasteurization process usually consists of three key steps:

Heating: The food is heated to a specific temperature, depending on the type of pasteurization, usually between 63°C (145°F) and 135°C (275°F).

Holding: The food is held at this temperature for a certain period of time to ensure that harmful microorganisms are effectively killed.

Cooling: The food is cooled quickly to prevent any remaining bacteria from multiplying.

In addition to these three main steps, in practice, especially for products such as milk, pre-cooling, pre-heating, clarification, standardization and homogenization are also carried out to ensure product quality and consistency.

Pasteurization is widely used in various fields:

Food, Dairy and Beverage Industry: This is the most important area of application for pasteurization and is used for the sterilization of products such as milk, juices and beer.

Pharmaceutical industry: for the sterilization of certain drugs and preparations.

Cosmetic industry: for the sterilization and preservation of certain cosmetics.

Chemical and paint industry: for the sterilization of certain chemicals and paints.

Q: Is the food completely sterile after pasteurization?

A: No. Pasteurization significantly reduces the number of microorganisms, but does not completely kill all microorganisms.

Q: What are the advantages and disadvantages of different pasteurization methods?

A: Different methods vary in terms of sterilizing effect, impact on food quality and processing time and need to be selected on a case-by-case basis.

Q: How does pasteurization affect the nutritional value of food?

A: The effect of pasteurization on the nutritional value of food is relatively small, but high temperature treatment may lead to the loss of certain nutrients.

Through the introduction of this article, I believe you have a deeper understanding of the pasteurization system. Pasteurization technology plays a vital role in ensuring food safety and extending shelf life, and its continuous development and improvement will continue to contribute to human health.